Different methods are applied to reduce the bacterial load of raw milk. The most commonly preferred method is heat treatment (Pasteurization, Thermization, Sterilization, etc.). Membrane process technology has come to the fore as a result of the trend towards alternative methods in order to save energy and eliminate the possible effects of beneficial bacteria and other beneficial components inherent in milk.

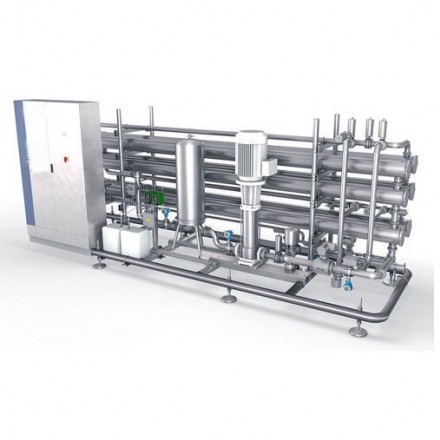

Microfiltration process; It can be applied at the point of raw milk intake or during the process (50-55 0C). Considering that it may cause bacterial accumulation in milk fat, it is recommended to first separate the milk fat through centrifugal separators, apply the microfiltration process to skim milk and mix the separated fat back into the milk.

Milk in the microfiltration process; It is sent to ceramic membranes consisting of pores of 0.4-1.4 μm size. While bacteria cannot pass through the pores and are retained, other milk components (protein-carbohydrate-mineral, etc.) pass through the membrane pores, thus the milk is cleared of bacteria.