Plate Heat Exchangers are the units where the Ice Cream Mix is cooled down to the Ageing Temperature (8-10 0C) after being pasteurised by Sp Makina Mix Pasteurisation Tank. Further cooling down to 4-6 0C is performed inside the Ageing Tank.

The cooling down should be applied very quickly after the milk reaches the desired pasteurisation temperature for preventing any negative result of over-heating and also the löse of time. Hence the capacity of PHE should be selected for cooling the milk in 15 or maximum 30 minutes.

Using Chilled Water for the entire cooling process will result with a high cost. For this reason; Mix Cooling PHEs are designed as 2-Stage.

1st Stage; Cooling Down from Pasteurisation Temperature to Ambiant T (25-30 0C) by mains water

2nd Stage; Cooling Down from Ambient Temperature to Ageing T T (8-10 0C) by Chilled water

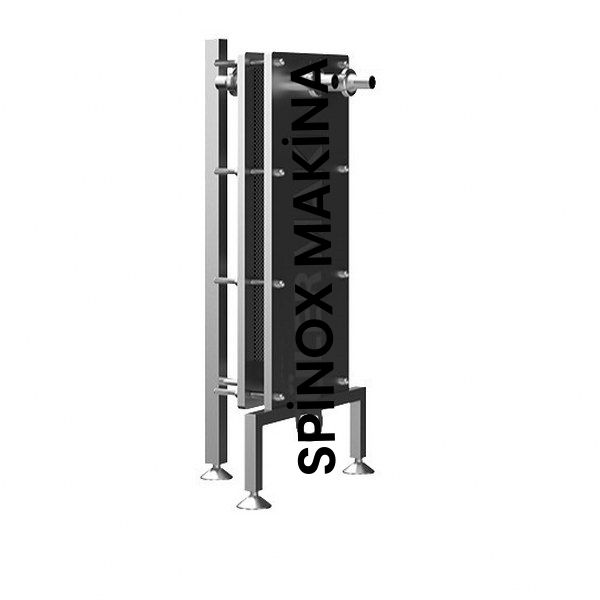

Equipment : Mix Cooling Plate Heat Exchanger

Capacity : 300 lt-h Z 30000 lt-h

Inlet Outlet T : 72-75 0C > 25/30 0C > 8/10 0C

Plate Material : ASII 316 L

Gasket Material : NBR-EPDM

Frame Material : Stainless Steel Covered

Conenctions : Rubber Insert / Flange

Cooling Media : Mains Water + Chilled Water